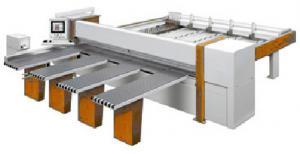

Work Cell Machining

A work cell uses separate machines for the processes of cutting part blanks and then machining those parts. Typical components include a panel saw, point-to-point machine, and edgebander.

Starting with the part information.

CADCode imports and translates parts data, from a multiplicity of file formats. This flexibility allows you, the end-user, to work in the design software of your choice, from a spreadsheet with parametric formulas to a generic CAD program to a specialized cabinet package.

Merge data from multiple sources.

Unique to CADCode is the ability to combine sources of information in a single production run – you can merge diverse data sources for a single job or multiple jobs and create code for all your parts without losing their respective job associations.

Multiple operations with one click.

CADCode’s work cell solutions cover all aspects of the machining – saw optimization and code, part label printing, and CNC machining center code generation. At the same time it optimizes the parts for cutting on the panel saw, CADCode will produce accurate, efficient, ready-to-run programs to machine part blanks on point-to-point machining centers (as well as routers, and horizontal boring/dowel insertion machines). It also generates the part label database with all of the information to be printed on your labels.

Mixing machinery is not a problem.

With an extensive and ever-growing library of machine posts, CADCode supports virtually all current CNC machinery brands and  models, empowering you to put together the best possible mix of components to fit your needs. When processing a job, CADCode can create machining programs for a group of CNC machines, regardless of brand or control. Additional features include automatic runfield control and handling of mirrored parts, and the ability to create and store multiple tool files for each machine.

models, empowering you to put together the best possible mix of components to fit your needs. When processing a job, CADCode can create machining programs for a group of CNC machines, regardless of brand or control. Additional features include automatic runfield control and handling of mirrored parts, and the ability to create and store multiple tool files for each machine.